Chapter 4 Product Identification and Transport

Product Identification and Transport

Transport and Storage

MONORAIL guide rails and AMS measuring systems are high-precision components that must be handled with care. To prevent damage during storage and transport, follow these instructions:

- Internal transport may only be carried out by trained personnel.

- Transport guide rails and accessories in their original packaging whenever possible to protect them from corrosion.

- Do not store products outdoors and protect them from impact damage and moisture.

- Storage in the original condition as delivered is recommended. High humidity, extreme temperatures and temperature fluctuations must be avoided. Otherwise there is a risk of condensation, corrosion and separation of the grease into thickener and oil.

- Only remove products from their original packaging at the installation location and immediately before assembly.

The packaging provided offers sufficient protection against damage to the products during proper transport and protects against corrosion caused by humidity and temperature fluctuations for eight weeks.

Products must be checked for damage and corrosion every eight weeks. If necessary, they should be cleaned with a suitable anti-corrosion agent and repackaged.

Transport Packaging

MONORAIL products are shipped in individual cartons, wooden crates or on pallets with multiple packaged items. Packaged items can be more than 6 meters long. For carton packaging with a gross weight of more than 30 kg, disposable or returnable pallets are placed underneath to facilitate stacking. If the packaging is more than 1.50 meters long, wooden slats are also placed under the cartons for reinforcement to prevent excessive sagging.

- Long packaged items must be lifted from the center of gravity at the center of the packaging.

- Wooden crates may be stacked up to a maximum of three levels.

- Pallets with cartons must not be stacked.

Auxiliary Tools

Any suitable lifting equipment may be used to move individual carriages, guide rails or packaged items, provided that this does not cause the guide rails to bend or otherwise damage the product.

- Lifting equipment must not damage the product or its packaging.

- Lifting equipment must minimize deflection.

Guide Rail Handling

WARNING!

Risk of injury from improper transport!

Guide rails may fall during transport and injure people nearby.

- Suspend long guide rails at multiple points using a crane during transport.

- The swing radius of long guide rails must be taken into account.

WARNING!

Risk of injury from carriage separation!

Carriages may separate from the guide rail during transport.

- Never tilt guide rails with carriages during transport or handling.

During storage, guide rails must be supported along their entire length.

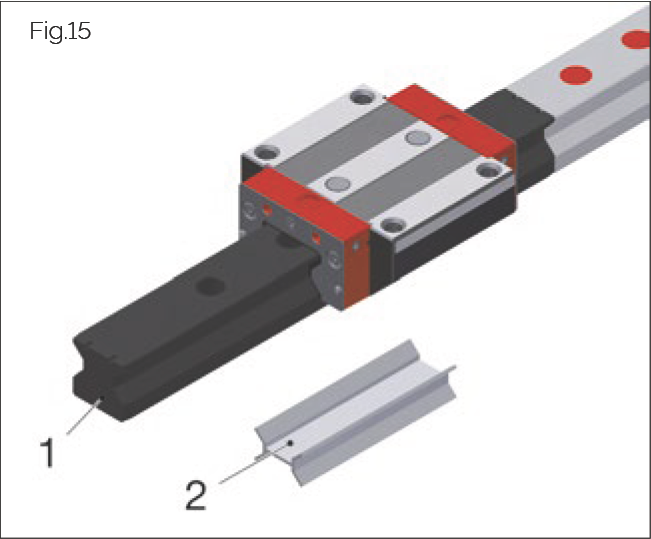

Cover Strip Handling

CAUTION!

Risk of injury from sharp cover strips!

Cover strips may have sharp edges that can cause cuts when touched.

- Wear protective gloves when installing cover strips.

- Transport cover strips rolled up in their original packaging whenever possible.

- Straight cover strips should be supported along their entire length and must not be bent.

- Observe the minimum bending radius for cover strips (Rmin = 0.4 m).

Carriage Handling

To prevent loss of rolling elements, ensure that carriages are protected from shock loads.

- To protect the rolling elements, always store carriages on the guide rail or on a transport/assembly rail for transport.

ATTENTION!

Risk of material damage from using transport rail for carriage installation!

Using a transport rail to install a carriage on the guide rail may cause rolling elements to fall out.

- Do not use transport rails for carriage installation.

- Use MRM or MBM assembly rails to install carriages on guide rails, see also page 60 "Replacing defective components".

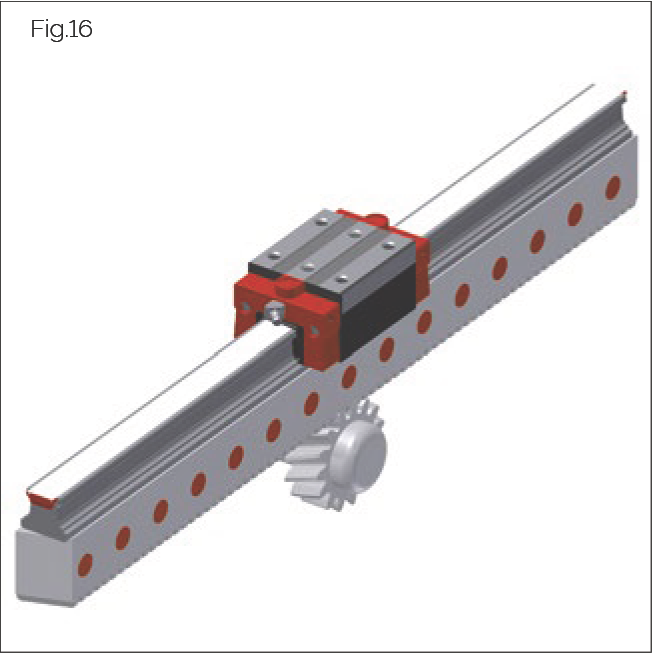

MONORAIL BZ

MONORAIL BZ systems are equipped with aluminum L-profiles for increased transport safety and handling convenience. BZ is packaged in wooden crates together with wooden pads that protect the guide rails from tipping and sliding. All steel parts are treated with anti-corrosion agent and wrapped in VCI film.

After successful system installation, the aluminum profile is dismantled and can be disposed of. Return transport can be arranged on a case-by-case basis with SCHNEEBERGER GmbH, which may include all installation components (if applicable).

Measuring System Handling

ATTENTION

Risk of material damage from magnetic fields!

The magnetic measuring tape of AMS guide rails can be destroyed by direct contact with magnetic fields.

- Protect guide rails with integrated measuring tape from magnetic fields.

- Do not use lifting magnets for transport.

- Protect the read head from strong vibrations or shocks.

- Always transport the read head installed in its housing whenever possible. Only remove the read head from the housing when installing the carriage on the guide rail.

- Always remove the read head before installing the carriage.

- During storage: For AMSABS measuring systems, do not remove the activation strip (see page 18 "Preparing the measuring system for installation") from the power supply on the electronics housing. Only activate the battery during commissioning.