7. Lubrication

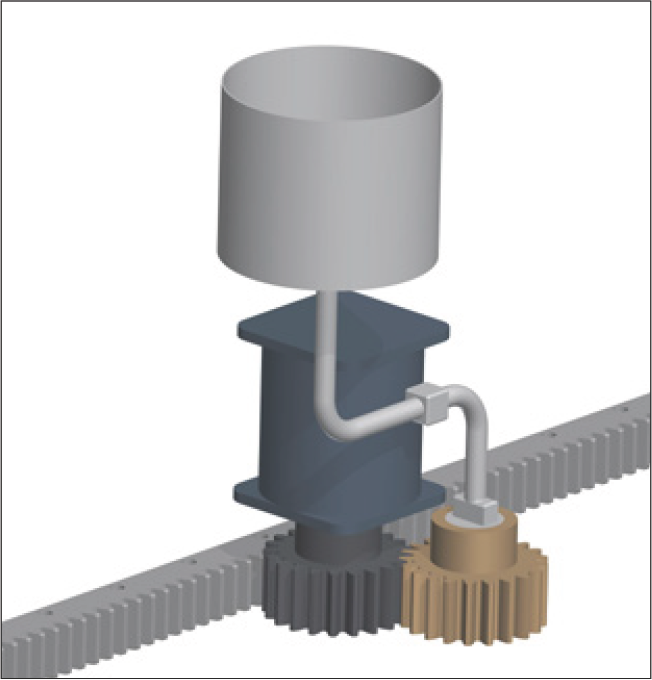

Lubrication device with felt pinion

Sufficient lubrication with a lubricant suited to the conditions of use is necessary to ensure that the rack drive continues to work properly. Lubrication protects from wear and corrosion and reduces friction.

Apart from the initial lubrication, the equipment must be re-lubricated regularly during installation.

Normally electrically driven lubrication cartridges are used for lubrication. Lubrication greases NLGI 00 to NLGI 0 are applied to the drive pinion or the gear rack with a felt pinion. Please note that the felt pinion wears over time and is subject to natural wear and tear. Therefore it must be checked at regular intervals and replaced if necessary.

A typical lubricant is Klüber Microlube GB 0.

8. Pinion/Gear Rack Operating Conditions

You must ensure that the pinion between the pinion and gear rack is set correctly.

When freewheeling, the guide block should be moved evenly over the length of travel (ensure that it has not been distorted during installation). With vertical axes the machine table must be secured according to the instructions.

In the event of jams, the distance between the gear rack and the guide should be measured again using a dial gauge.

9. Maintenance

9.1 Shutting Down, Preparation

The machine in which the drive system is installed must be shut down during maintenance. The machine must be disconnected from the power supply before maintenance work. With vertical axes the slideway must be secured according to the instructions.

9.2 Visual Check

- Check the whole drive system for external damage and leaking lubrication by a thorough visual check

- The pinion and gear rack must be cleaned

- The whole drive system must be checked for external damage and leaks with a thorough visual check

- Defects or leaking parts must be repaired immediately

10. Dismantling

10.1 Preparatory Measures

Shut down the machine in which the drive system is installed. The machine must be disconnected from the power supply before you start work. Ensure that it is possible to dismantle the gear system without any risk to people on the machine.

The gear rack and gear unit must only be dismantled by trained specialists with the necessary knowledge. With Z axes, the machine table must be secured as in the instructions.

The positive locking device on the machine table must be disconnected when dismantling the gear racks and the gear unit. If the machine table is not secured properly for Z axes, it may drop due to its own weight and cause damage to people and equipment.

The fixing screws must be undone. After that the gear rack can be removed from the pressed fitting with a suitable tool.

10.2 Removing the Gear Rack

- Remove the gear racks carefully, so as not to damage the gear system and adjacent parts

10.3 Replacing Spare Parts

- When installing new gear racks, use new screws (see 5.2) and pin to fit them

- Re-fit the spare gear racks in accordance with 5.2

- Select the next larger dowel pin, then specified in 5.2 (only the standard sizes as given in 5.2)

- Ream the all the holes to the correct tolerance dimension

- Finally fix the gear racks with the dowel pins

11. Disposal

| Material Category | Disposal Method |

|---|---|

| Gaskets | Must be disposed of as composite materials (metal/plastic) |

| Metal |

Separate the drive system as far as possible into:

|

| Hoses | Must be disposed of in the same way as plastic |

| Felt gear wheels | Must be disposed of in the same way as residual oil-containing waste |

12. Tightening Torques

The tightening torques specified for headless screws DIN EN ISO 898-1 are arithmetical values and do not apply to friction factor μ=0.125.

| Strength Class | Tightening Torque (in Nm) | ||||||

|---|---|---|---|---|---|---|---|

| M6 | M8 | M12 | M16 | M20 | M30 | M36 | |

| 10.9 | 13 | 31 | 108 | 265 | 540 | 1970 | 3600 |

| 12.9 | 16 | 40 | 135 | 330 | 660 | 2300 | 4100 |

Screws of strength class 10.9 must be used for soft or inductively hardened gear racks and strength class 12.9 for case-hardened and through-hardened gear racks.

A more even preload force is obtained if the screws are lubricated with a grease containing MoS2 and they are tightened using a torque wrench.