Chapter 5 Preparation for Installation

Preparation for Installation

5.1 Required Tools and Equipment

Installing MONORAIL MR/BM/BZ

- MRM assembly rail (for MONORAIL MR) or MBM (for MONORAIL BM)

- Whetstone and polishing pad

- Suitable solvent (e.g. white spirit)

- Lubricating oil or grease

- Grease containing MoS2 for fastening screws to ensure consistent and optimal screw forces

- Torque wrench

- MWM installation carriage (for MONORAIL MR)

- Guide rail fastening screws

- Wrenches, screwdrivers and Allen keys (for installing lubrication fittings and additional wipers)

- Soft cloths

- Corrosion protection

Additional Tools for Installing MRK/BRK Plastic Plugs

- Plastic mallet and pad

Additional Tools for Installing MRS/BRS Brass Plugs

- MWH/BWH hydraulic assembly tool and MZH hydraulic cylinder (with hydraulic unit)

- Scalpel, brass brush and compressed air gun (for installation)

- Hand drill, tap, drill bit, center punch and socket head cap screw (e.g. DIN 912/ISO 4762) (for removal)

Additional Tools for Installing MRZ Steel Plugs

- MWH/BWH hydraulic assembly tool and MZH hydraulic cylinder (with hydraulic unit)

- Hand drill, tap, drill bit, center punch and socket head cap screw (e.g. DIN 912/ISO 4762) (for removal)

Additional Tools for Installing MAC/BAC Cover Strips

- MWC or BWC assembly tool (for installation)

- Flat-head screwdriver and small Allen key (for removal)

5.2 Packaging Material

Carton packaging is used for individual guide rail deliveries and system deliveries. Wooden crates are available for certain countries or special requirements at an additional charge. These wooden crates are IPPC (International Plant Protection Convention) treated. Carriages are individually packaged in cartons.

In all cases, carriages and guide rails are wrapped in VCI film before delivery to protect them from corrosion. System deliveries use corrugated cardboard pads (for carton packaging deliveries) or maritime pine boards (for wooden crate deliveries). Accessories and lubrication fittings are included.

5.3 Condition as Received

Individual Packaging

All guide rail components are delivered unassembled in individual packaging. Accessories are included in separate packaging.

Unless otherwise specified by the customer, all standard lubrication fittings are opened and closed with set screws (S99/S98). Lubrication fittings that are not required are closed. Individual carriages are delivered on transport rails to protect the rolling elements.

AMS measuring systems are installed and ready for plug-and-play, with electrical accessories and cables packaged together with the mechanism. In the delivered condition, the read head may be installed in its housing or packaged separately as a separate component.

System Delivery

System delivery means that the carriages are installed with all accessories and packaged together with the guide rail in the same packaging. Lubrication fittings on the carriages are prepared according to customer specifications. Lubrication fittings are installed as specified or supplied separately in packaging. For AMS systems, the carriage is installed with all accessories and mounted on the guide rail.

5.4 Corrosion Protection

The external surfaces of carriages and guide rails are treated with hardened anti-corrosion protection. Rolling elements are protected with mineral oil-based anti-corrosion protection. Grease protection is also available on request. Carriages and guide rails are wrapped in VCI film. For special requirements such as overseas transport, additional precautions are taken.

5.5 Unpacking and Checking Delivery

ATTENTION!

Risk of material damage from improper unpacking!

Cutting into the measuring system groove may damage the measuring tape.

- Only cut on the top or bottom side of the guide rail.

- Never cut into the groove.

ATTENTION!

Risk of material damage from premature unpacking!

Premature unpacking may damage the read head.

- Only remove separately packaged read heads from their packaging immediately before installation.

- Open profiled linear guideways (including those with integrated measuring systems) directly at the installation location, immediately before installation. Use a commercially available film knife to carefully cut open the anti-corrosion film without scratching any part of the guide rail.

- For guide rails with integrated measuring systems, extra care must be taken to ensure that cuts are only made on the top and bottom sides of the guide rail, and never in the groove, as this is where the measuring tape is located.

- Always support long guide rails at multiple contact points during handling.

- Keep carriages on the guide rail whenever possible. Always place separately packaged carriages on transport rails.

- Use MRM or MBM assembly rails to install carriages on or remove them from guide rails. After removal, keep the carriage on the assembly rail.

- Check the completeness and condition of the delivered parts. Pay particular attention to checking whether cover strips, lubrication fitting parts, washers, plugs, etc. are bent.

- Store delivered parts to allow temperature equalization before installation. Read the installation instructions and accompanying product documentation carefully before installation.

5.6 Preparing Locating Surfaces

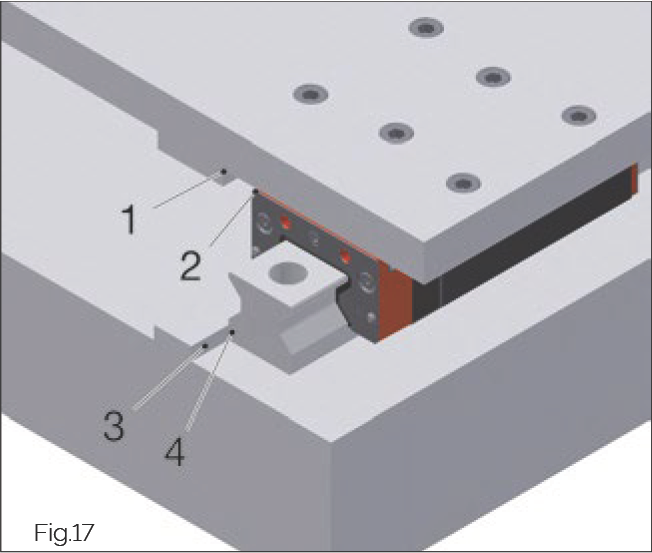

The locating surface of the guide rail is on the side away from the SCHNEEBERGER and type labels.

Locating surfaces are prepared as follows:

- Check the form and positional accuracy of the machine bed and mounting plate locating surfaces. If they do not meet specifications, rework the locating surfaces.

- Thoroughly clean all locating surfaces. Use a whetstone to remove burrs and surface irregularities.

- Ensure that the guide rail and mounting base are at the same temperature before and during installation.

- Use a suitable solvent (e.g. white spirit) to remove the anti-corrosion protection from the guide rail and carriage. Do not use any solvent that may damage plastic. Do not move the carriage during this process, as this may cause damage.

ATTENTION!

Risk of material damage from moving the carriage!

This may cause material damage.

- Never move the carriage while using anti-corrosion protection or suitable solvents.

- Lightly oil the locating surfaces of the guide rail and carriage.

5.7 Preparing Measuring System for Installation

Absolute measuring systems have an integrated battery-assisted power supply that ensures position information is retained even when the controller is switched off.

The measuring system is prepared as follows:

- Unpack

- Remove the cover plate from the housing (see 6.5.2 "Installing and connecting the read head")

- Activate power supply:

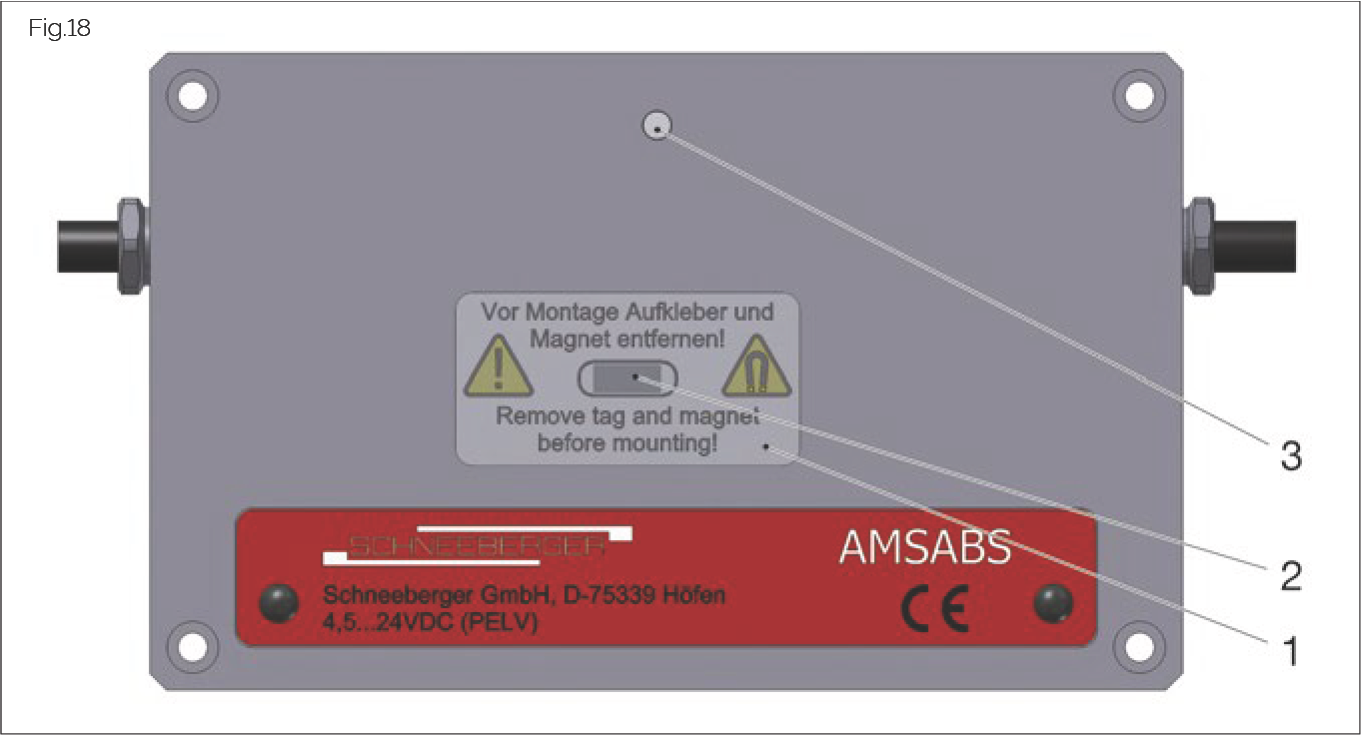

- Remove the activation strip and the magnet underneath it from the electronics housing (see figure)

- Install the read head

- When the read head is referenced, the LED briefly lights up green