Chapter 9-11 Maintenance, Disposal & Troubleshooting

Maintenance, Disposal & Troubleshooting

9.1 Visual Inspection Check List

During guideway maintenance, it is essential to ensure the following conditions are not damaged and can prevent damage to them through visual inspection:

- Check the guideway surface for damage.

- Check the seals, see page 58 "Checking the results of the installation".

- Check additional seals (if installed) for damage/wear.

- Check whether the carriage has sufficient lubrication (whether lubricant is discharged from the carriage).

- Remove the carriage and check for dust (see "Handling the carriage" on page 20).

- Remove the carriage and check for damage to plastic parts (see "Handling the carriage" on page 20).

- Remove residual chips from the vicinity of the guideway.

9.2 Cleaning

ATTENTION!

Risk of material damage due to improper cleaning!

May cause damage to plastics and guideways.

- All parts should only be wiped with cleaning agent, using cleaning alcohol or white spirit. Do not use any cleaning agents or solvents that could damage plastics.

- Clean the guideway with a soft, lint-free cloth. Do not use compressed air.

- Avoid direct contact of tools with the guideway magnetic measuring tape.

9.3 Replacing Defective Components

ATTENTION!

Risk of material damage posed by bending sensor slide springs!

When transferring carriages with housing for the AMS measuring system with built-in read head to/from guideway, sensor slide springs can become bent.

- Dismount the read head before transferring carriage to/from guideway.

ATTENTION!

Risk of material damage posed by scratching the measuring scale!

Swarf caught beneath metal wipers can scratch the magnetic measuring scale.

- Only use metal wipers designated for the AMS measuring system on guideways with magnetic measuring scale.

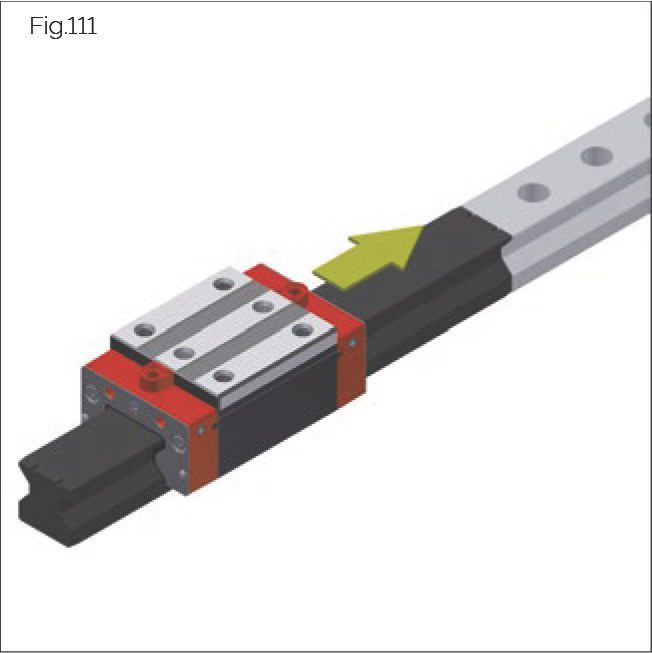

Fig.111

- The carriage and guide rail form a single unit. In the case of matched designs, ensure that the carriages of different guide rails are not interchanged.

- To prevent rolling elements from being dislodged from carriages, use an MRM/MBM assembly rail when transferring carriages to and from guide rail. The MRM/MBM assembly rail is not included in the standard delivery.

- Should one carriage become damaged, replace all carriages. Should it be unknown which accuracy levels are installed, a G0 system can be installed. This ensures that the original accuracy levels are achieved.

Carriage Replacement Procedure

Identifying the carriage for ordering spare parts:

- The relevant carriage can be identified by its label, see 3.3 Labelling of guide rails and carriages on page 9.

Spare Parts

- STP front plate

- QAS cross wiper for MONORAIL MR/BM

- FRB front panel for MONORAIL MR

- ZCV additional wiper for MONORAIL MR and ZBV for MONORAIL BM

- ASM metal wiper for MONORAIL MR and ABM for MONORAIL BM

- SPL lubrication plate

- Screws

Guide Rail Replacement Procedure

Identifying the guide rail for ordering spare parts:

- The relevant guide rail can be identified by its label, see 3.3 Labelling of guide rails and carriages on page 9.

Spare Parts

- Screw covers

- Screws

- Transfer carriages onto MRM/MBM assembly rails.

- Leave carriages on assembly rails during transportation or storage. Ensure that carriages and associated guide rails are not interchanged.

- Individually transfer carriages back onto their associated guide rail from assembly rails.

9.4 Replacing the Read Head

CAUTION!

Risk of crushing due to moving axis!

May cause personal injury.

- Before replacing the read head, switch off the main switch and ensure it cannot be switched on again. If necessary, secure the axis.

ATTENTION!

Risk of material damage due to short-circuit current!

The electronics in the read head can be damaged by short-circuit current.

- Before replacing the read head, disconnect the power supply and ensure it cannot be restored without authorization.

Removing the Read Head

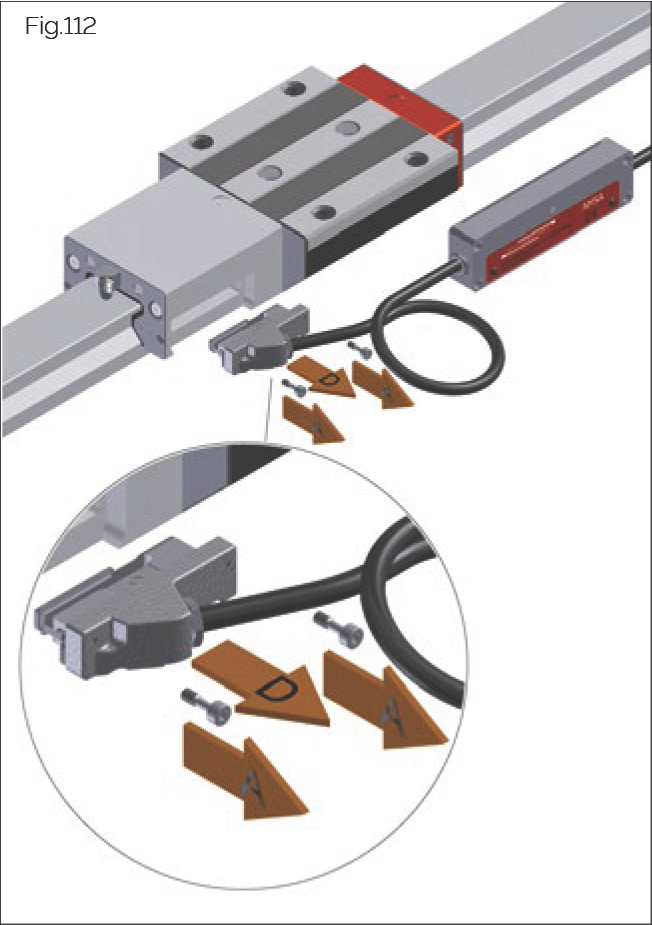

Fig.112

- Switch off the main switch and ensure it cannot be switched on again.

- If necessary, remove the protective cover.

- Ensure proper handling of the decommissioned axis.

- Disconnect the read head connecting cable.

- Disconnect the sensor cable from the electronics housing (if applicable).

- Loosen the fastening screws securing the read head to the housing.

- Remove the cover plate screws for AMSABS 4B.

- For AMSABS 3B, slide the installed read head sideways out of the guideway until it is completely free to rotate, moving it away from the mounting surface at the correct angle.

- Carefully remove the read head from the mounting surface at the correct angle.

- Document the fault and serial number and package the read head.

Installing the Read Head

- Check the read head mounting surface (housing) for contaminants.

- Clean the magnetic measuring tape.

- Carefully unpack the new read head.

- If necessary, install the battery tray (AMSABS).

- Carefully insert the read head into the recess in the housing at the correct angle, ensuring correct positioning.

- For AMSABS 3B and 4B: Slide the read head parallel to the guideway until it stops.

- The measuring system will automatically identify its absolute position (during commissioning).

- After the controller is powered on, the LED will light up green.

- Tighten the fastening screws securing the read head housing (see page 74 "Screw tightening torques").

- Connect the cable to the separate electronics housing. For this, use the wiring diagram on page 52 "Routing electronics housing and cables".

- Switch on the power supply.

- For AMS with separate electronics housing: Ensure the LED lights up green.

- Check the machine zero point and recalibrate if necessary. If required, perform a reference run.

- Move the axis to the stroke limiters.

ATTENTION!

Risk of material damage due to collision!

Failure to check and adjust (if necessary) the machine zero point may cause machine components to collide with other components.

Note: Position identification between equivalent reference marks may vary by ± 0.5 mm depending on the read head.

9.5 Battery AMSABS / AMSABS 3L

Battery: Lithium Type AA- LS 14500- 3.6V 2450 mAh- SAFT

Battery Status Display

For AMSABS, low battery status is indicated by the operating status LED and, if necessary, by the machine controller.

Operation

The electronics housing (sensor unit) contains an accumulator and buffer battery that ensure system functionality even when the machine is switched off. When the machine is switched off for short periods, the accumulator provides coverage for up to 4 weeks. When the machine operates regularly, the buffer battery guarantees sensor unit functionality for many years. This means that in typical use cases where the machine operates regularly, the accumulator and buffer battery are protected from premature discharge. This ensures that the original accuracy class is achieved.

If the external power system is switched off for an extended period, the position measuring system remains functional. The battery maintains system position measurement for up to 5 years, although regular angular movement of the read head is required. This process is described on page 27 "Commissioning instructions".

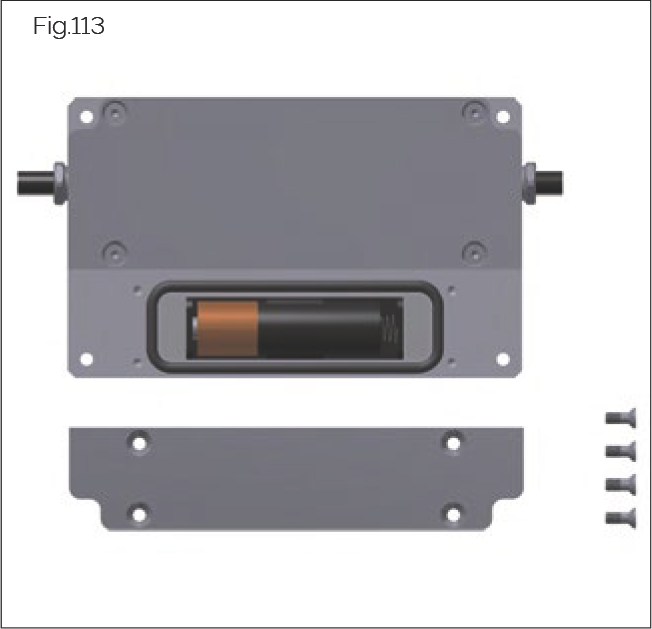

Fig.113

- Loosen the battery compartment on the back of the electronics housing.

- Remove the old battery.

- Insert the new battery, ensuring correct orientation.

- Check that the O-ring is correctly installed in the groove and ensure the O-ring, groove, and support surface are clean.

- Reinstall the battery compartment and tighten with screws.

- Dispose of old batteries properly according to applicable national regulations.

Only use batteries with a manufacturing date no more than one year old. Before replacement, check the manufacturing date marked on the battery.

| Country | Germany | USA | France |

|---|---|---|---|

| Description | Year/Month/Day | Year/Day | Year/Day/Code |

| Example | 18.02.23A | 18.054 | 18.054.A123 |

| Meaning | Within 14 months after February 18, 2023 | Within 14 months after day 54 of 2018 | Within 14 months after day 54 of 2018, France A123 |

9.6 Checking and Replacing Accessories and Wear Parts

9.6.1 End Plates and Additional Seals

Ensuring proper carriage function is a prerequisite for ensuring the guideway provides contamination-free lubrication and prevents contaminants from entering. Generally, seals are designed to be maintenance-free. They should be regularly checked for damage and wear at specified intervals.

Seals on end plates and additional seals should be regularly checked for damage, at least every 6 months, and replaced if necessary.

Replacing Cross Seals and Additional Seals

DANGER!

Risk of death due to loss of rolling elements!

For MONORAIL BM, the end plate is part of the rolling element recirculation unit. Removing the end plate will cause loss of rolling elements. Possible consequences include death and serious injury.

- For MONORAIL BM, the end plate of the carriage must not be removed under any circumstances.

When replacing cross seals and additional seals, remove the fastening screws from the end plate.

The following must be observed when performing this operation:

- For MONORAIL BM, the end plate must not be removed under any circumstances.

- For MONORAIL MR, the end plate does not need to be removed to replace the cross seal.

- Always use an assembly guideway to transfer carriages to and from the guideway.

- For carriages with measuring systems, always remove the read head from the housing before transferring carriages to and from the guideway.

Cross Seals

Checking Cross Seals

Regularly check cross seals for wear and replace if necessary.

Replacing Cross Wipers in the Case of MONORAIL MR

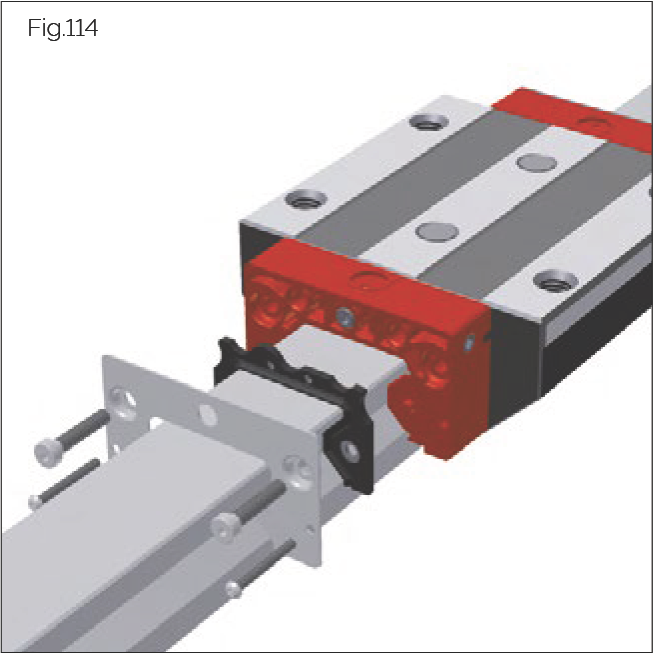

Fig.114

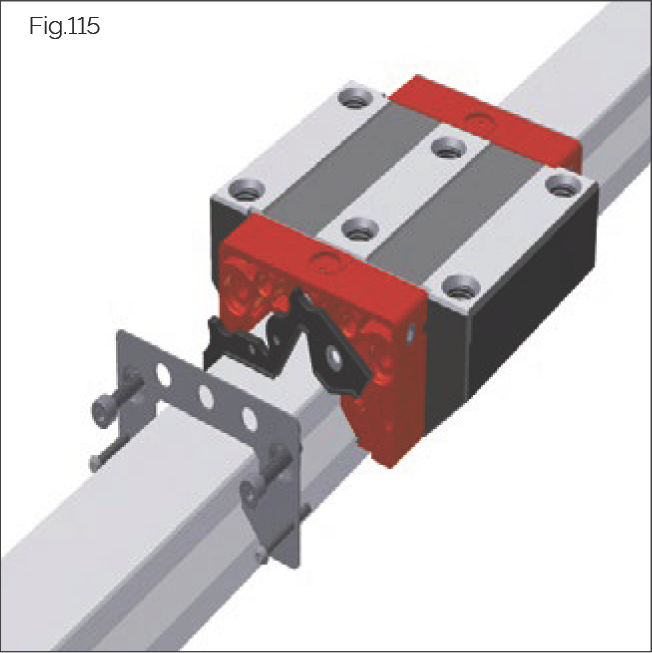

Fig.115

- Leave carriages on the guideway.

- Remove the upper and lower screws.

- Remove front panel and accessories (where applicable) from the front plate (can be left on the guideway).

- Disengage the cross wiper from the front plate and, to remove it, pull over the guide rail while holding the front plate in place.

- Pull the new cross wiper onto the guide rail and press it into the front plate (taking care with the rotation lock).

- Slide accessories and front panel back onto the front plate.

- Tighten the screws. See 12.2 Screw tightening torques on page 74.

Replacing Cross Wipers in the Case of MONORAIL BM Front Plates

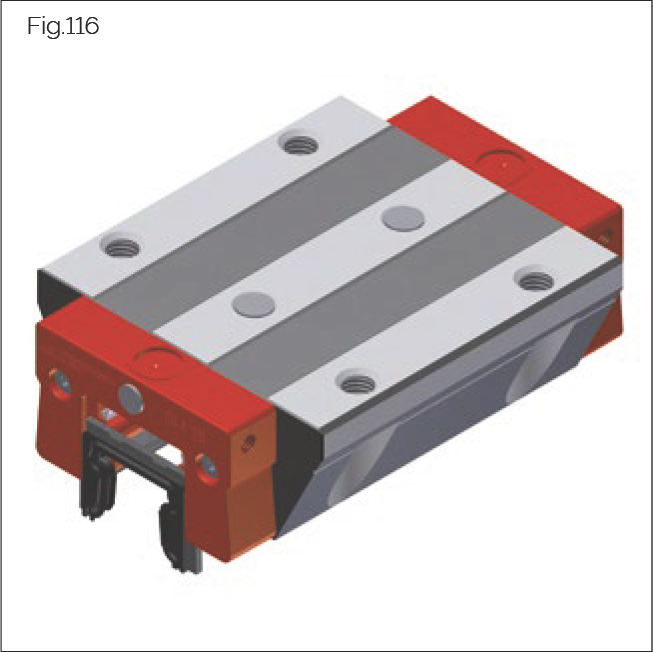

Fig.116

In the case of MONORAIL BM, only the cross wipers in the front plate should be replaced.

The screws of the front plate must not be loosened during this process.

- Use an assembly rail to transfer the carriage from the guideway.

- Pull the defective cross wiper downward and out of the front plate housing.

- Fully slide the cross wiper into the guideway groove of the front plate.

→ The cross wiper will snap in audibly.

- Remount the carriage onto the guide rail.

ZCV/ZBV Additional Seals

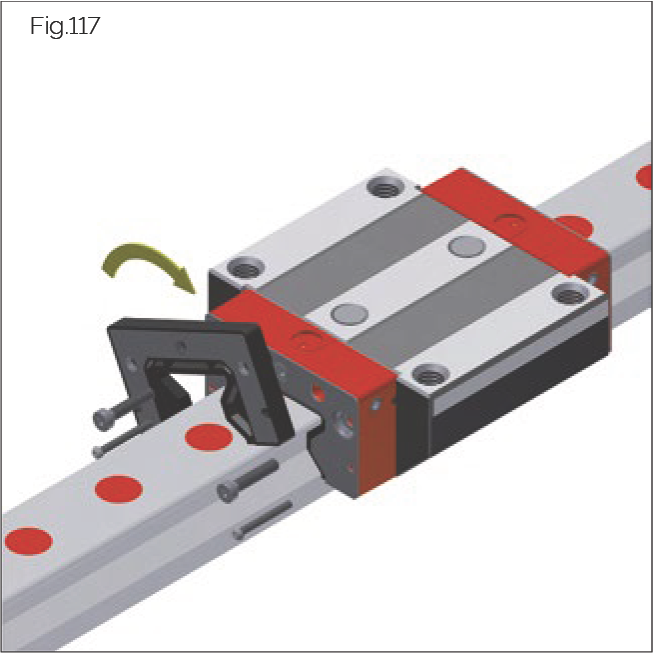

Fig.117

Their flexibility allows additional seals to be replaced directly on the guideway. They can also be installed or removed from carriage end plates that cannot be removed from the guideway.

Note: Lubrication fittings on the end plate are sealed with stop screws. During installation of ZCV/ZBV additional seals, these stop screws are covered. When screwing lubrication nipples into additional seals, the stop screws underneath must be removed.

- Loosen the screws on the carriage end plate.

- Move the additional seal a few millimeters away from the end plate while holding the end plate.

- Pull the seal off the guideway and replace 4 metal surfaces (if necessary).

- Pull the new additional seal over the guideway cross-section (or track end).

- Press the seal onto the end plate, aligning on its surface through the centering pin.

- Ensure the seal is evenly positioned and tighten the screws. For maximum tightening torque, see page 74 "Screw tightening torques".

Longitudinal Seals

Longitudinal seals are firmly connected to the carriage or housing.

Checking Longitudinal Seals

To identify damage to longitudinal seals, completely remove the carriage and perform a visual inspection of the sealing lip.

Replacing Longitudinal Seals

For longitudinal seals firmly connected to the carriage or housing that are damaged, the entire carriage must be replaced.

Metal Seals

Checking ASM/ABM Metal Seals

- Check the end plate for mechanical damage and whether the gap with the guideway profile is evenly positioned.

- Replace or readjust the metal seal based on the results.

Replacing ASM/ABM Metal Seals

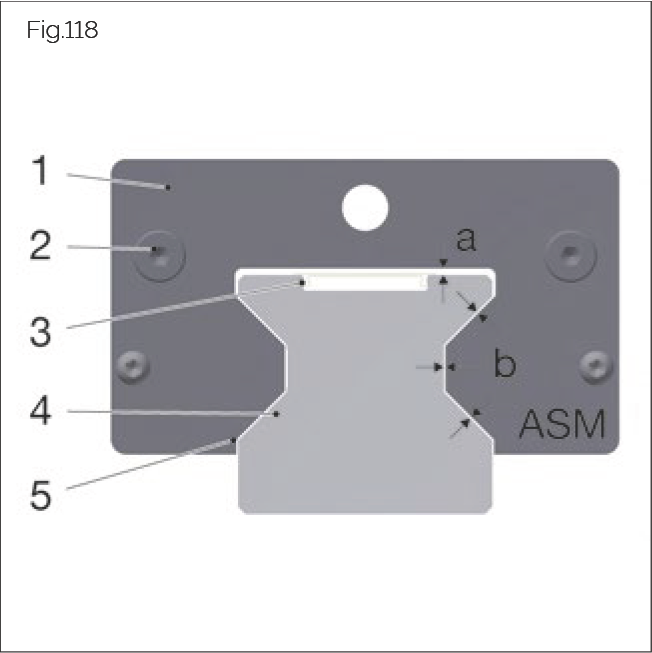

Fig.118

- Loosen the screws on the end plate.

- Pull the metal seal from the guideway end.

- Slide the new metal seal over the guideway.

- Tighten the screws until the metal seal can no longer be moved by hand.

- Hold the metal seal and tighten the screws. For tightening torque, see page 74 "Screw tightening torques".

- Check the gap after tightening the screws.

- When the carriage is mounted on an AMS guideway, ensure the gap is maintained above the MRC cover strip or installed MAC cover strip. This metal seal can be identified by the end plate.

Gap Dimensions

- a = 0.15 mm ± 0.05 mm

- b = 0.25 mm ± 0.05 mm

When using AMS guideways, ASM-A metal seals must be used. These are shortened by 2 mm on the lower side of the front arm. The metal seal can be identified by the end plate.

9.6.2 Rail Covers

Rail covers include plugs, cover strips, and bellows. These are prerequisites for ensuring the proper functioning of the carriage seal system and one of the factors responsible for ensuring that the guideway provides an extended service life. Rail covers should be checked at regular intervals (at least every 6 months) for damage and wear, and replaced where necessary.

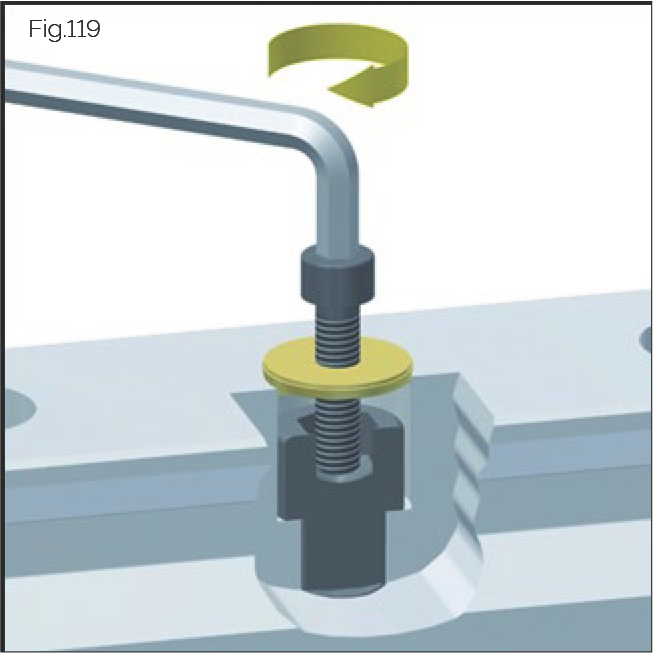

Fig.119

Plugs

Plugs must be fitted flush with and parallel to the guide rail surface. Protruding or scratched plugs may cause damage to carriage wipers. Where plugs sit too deeply, this may lead to the build-up of dirt in the guide rail fixing holes or to damage to carriage wipers caused by the sharp edges of these holes.

Checking Plugs

Check plugs for dirt and swarf in the fixing holes or on the guide rail surface. Dirt and swarf that are not wiped away as the carriage passes over the guide are indicative of improperly functioning plugs. Plugs should be replaced in this case and carriage wipers checked.

MAC/BAC Cover Strips

Checking MAC/BAC Cover Strips

Replace cover strips in the following cases:

- Cover strip is bent or scratched

- Cover strip has longitudinal offset

- Cover strip groove has loose ends

- Cover strip is loose

Replacing MAC/BAC Cover Strips

For cover strip replacement, see page 44 "MAC/BAC cover strips".

FBM/FBB Bellows

Checking Bellows

Check bellows for damage such as tears or holes. Check whether bellows slide smoothly over the guideway. If damaged, bellows must be replaced; if applicable, also check the MONORAIL guideway for damage or contamination.

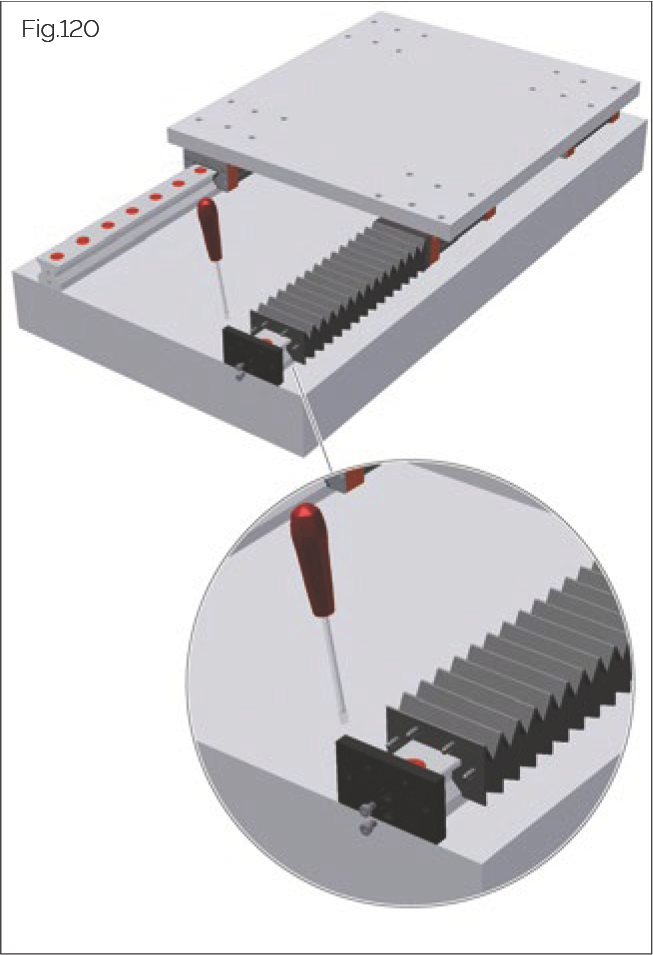

Fig.120

Replacing Bellows

- Use a flat-head screwdriver to loosen the bellows from the fastening plate.

- Loosen the fastening screws on the end plate.

- Remove the end plate.

- Clean the guideway.

- Check guideway plugs and cover strips for damage.

- Install the new pre-assembled bellows (with frame) onto the guideway.

- Snap the rivets at the bellows end into the corresponding holes on the adapter plate.

- Install the end plate.

- Snap the rivets at the bellows end into the corresponding holes on the adapter plate.

- Check whether the bellows is correctly positioned and has freedom of movement.

9.7 Spare Parts - Availability

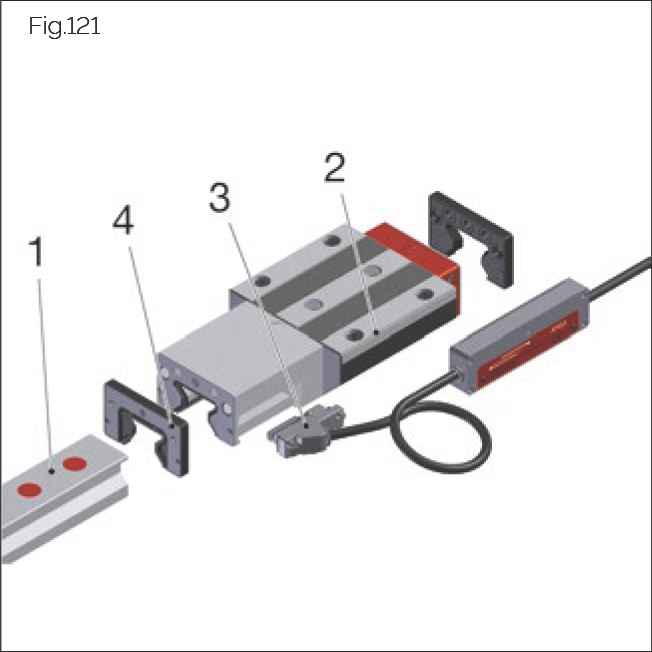

Fig.121

All precision-machined guideways in the MONORAIL MR, BM, and AMS product lines consist of four main subassemblies:

- Guideway

- Housing (with read head housing if applicable)

- AMS sensor unit

- Accessories

These subassemblies may lead to new structural versions due to technical improvements. This means that the internal construction of subassemblies may change with technology, material usage, quantity, and interaction of constituent parts.

SCHNEEBERGER commits to providing compatible complete subassemblies after delivery of the MONORAIL system, and therefore maintaining availability of complete subassemblies that are also compatible. Maintenance provides fixed service availability for all products without affecting availability. Parts from these subassemblies are only maintained and provided for up to 1 year before new subassemblies are introduced. This means subassemblies replaced by new structural versions are discontinued 1 year before expiration.

For complete subassemblies, SCHNEEBERGER provides compatible subassemblies that are identical in mechanical geometry for up to 10 years after the product is discontinued from the market. Any exceptions will be communicated individually.

Chapter 10 - Disposal

NOTE: Products and packaging materials, including plastics, metals, batteries, electronic components, wood, and lubricants, should be disposed of or recycled by the operator in accordance with locally applicable national or regional regulations.

Chapter 11 - Troubleshooting the AMS Measuring System

Operating State Display

The AMSA 3B, AMSA 4B, AMSD 3B/4B, and AMSABS measuring system versions are fitted with a service LED in the electronics housing of the read head that displays the different measuring system operating states.

| LED | Error | Repair |

|---|---|---|

| Red continuous | Encoder defective, internal hardware error | Replace sensor |

| Red flickering | External power supply outside tolerance | Check power cable from controller |

| Red/green flickering | Internal sensor signal too low (< 60%) | Remove dirt: Read head, receiving housing, and measuring scale must be cleaned. Check lubrication line connection. Replace read head. |

| Red/green flashing | Internal sensor signal too high (> 140%) | Check lubrication line connection. Replace read head. |

| Green flickering | Encoder damaged, internal sensor voltage > 5V | Replace encoder |

| Green flashing | Encoder damaged, internal sensor voltage < 0.6V | Replace encoder |

| Red flashing | Not referenced, absolute position incorrect | Repeat referencing |

| Green + red flashes | Backup battery empty | Replace battery |

| Red + green flashes | At least 1 CNC error detected | Fix controller error as required |

| Red + green flashes | Setting up DRIVE-CLiQ communication | No action required |

| Green continuous | System is working normally | No action required |