不同的应用领域需要直线导轨和循环单元的不同特性。

产品选择时需要考虑多种参数和因素。以下详细说明这些关键考量。

行程 H 与导轨长度 L 的关系

Relationship between stroke H and length of the guideway L

行程 < 400 mm

If the stroke is below 400 mm

行程 > 400 mm

If the stroke is above 400 mm

| L | = 直线导轨长度 (mm) Length of the linear guideway in mm |

| H | = 可能行程 (mm) Possible Stroke in mm |

计算滑块长度 K

Calculating the cage length K

对称行程

If the stroke is symmetrical

非对称行程

If the stroke is asymmetrical

H > H₁ + H₂

H₁₂ = H₁ + H₂

| K | = 滑块长度 (mm) Cage length in mm |

| L | = 直线导轨长度 (mm) Length of the linear guideway in mm |

| H | = 可能行程 (mm) Possible Stroke in mm |

| H₁ | = 大部分行程 = H/2 (mm) Large partial stroke in mm = H/2 |

| H₂ | = 小部分行程 = H/2 (mm) Small partial stroke in mm = H/2 |

| H₁₂ | = 有效部分行程 (mm) Effective partial stroke in mm |

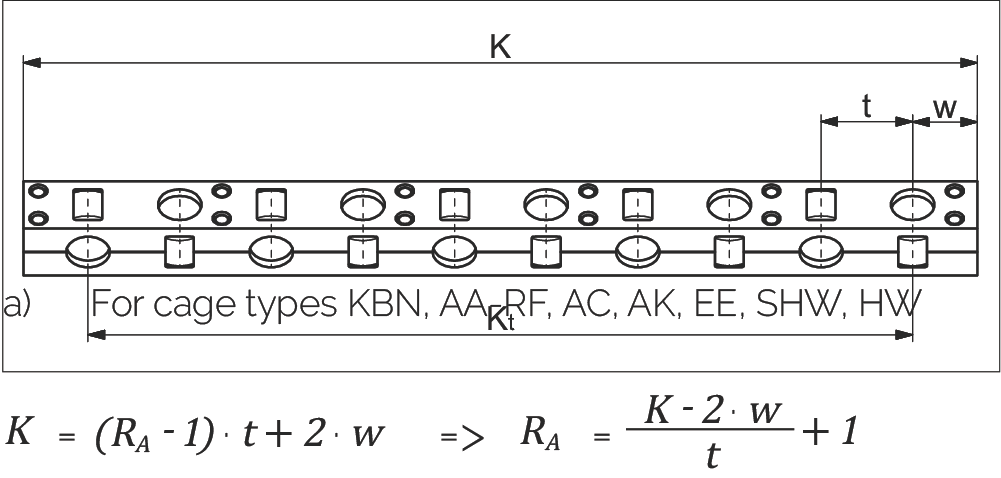

计算每个滑块的滚动元件数量 (RA)

Calculating the number of rolling elements (RA) per cage

a) 滑块类型:KBN, AA-RF, AC, AK, EE, SHW, HW

For cage types KBN, AA-RF, AC, AK, EE, SHW, HW

或

b) 滑块类型:KBS

For cage type KBS

或

| K | = 滑块长度 (mm) Cage length in mm | t | = 滑块分度 (mm) cage division in mm |

| RA | = 每个滑块的总可用滚动元件数 Total available rolling element per cage | Kt | = 负载长度 (mm) Load-bearing length in mm |

| w | = 从滑块起始到第一个滚动元件中心的距离 (mm) Distance from cage start to the middle of the first rolling element in mm | tz | = KBS 滑块中间段的长度 (mm) Length of the middle section for the KBS cage |

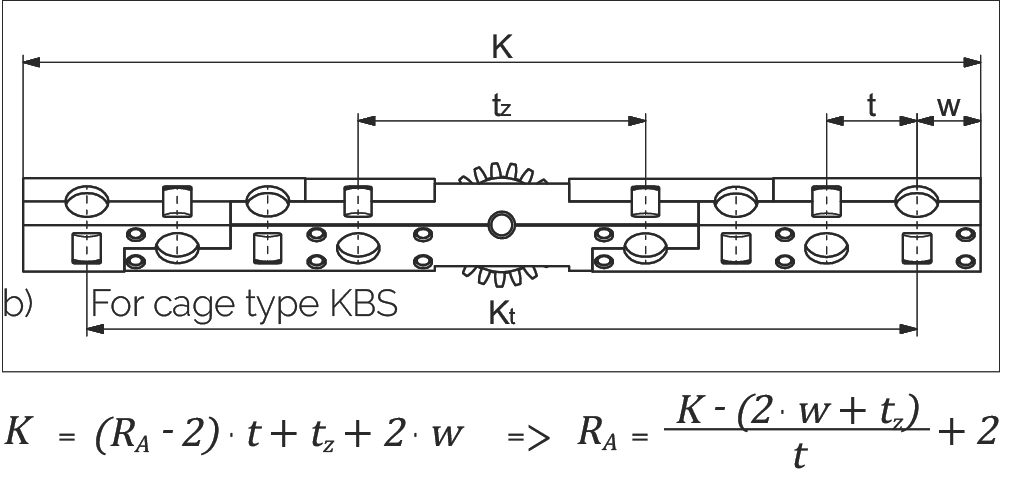

滑块长度 K 与平均导轨间距 Q 的关系

The relationship between the cage length K and the average guideway spacing Q

| K | = 滑块长度 (mm) Cage length in mm |

| Q | = 平均直线导轨间距 (mm) Average linear guideway spacing in mm |

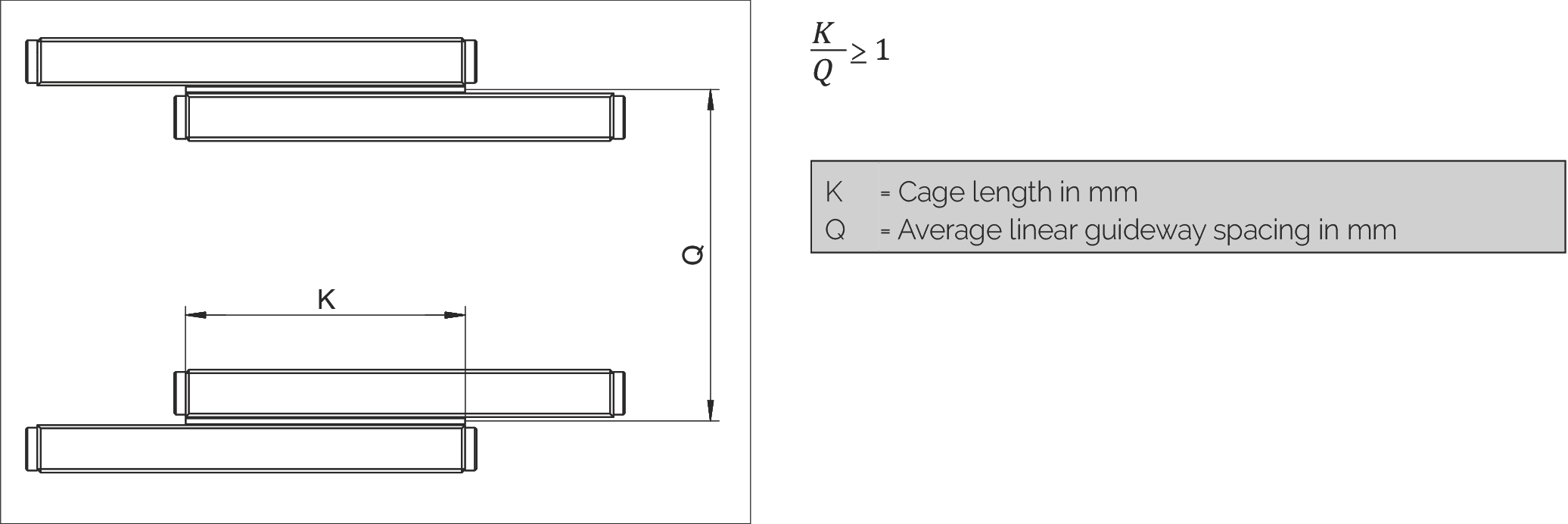

超行程滑块的最大允许安装比例

The maximum permissible installation ratio in the case of overrunning cages

当需要在长导轨轨道上移动短工作台时,超行程滑块是一种有效的解决方案。在这种情况下, 导轨的短轨必须配备圆形导入部(特殊版本 EG,参见第 7.3 章),以使超行程滑块产生的脉动尽可能小。

最大允许安装比例 L : L₁

Maximum permitted installation ratios L to L₁:

| 固定式导轨 for fixed guideways | 1 : 2 |

| 叠置式导轨 for laid on guideways | 1 : 4 |

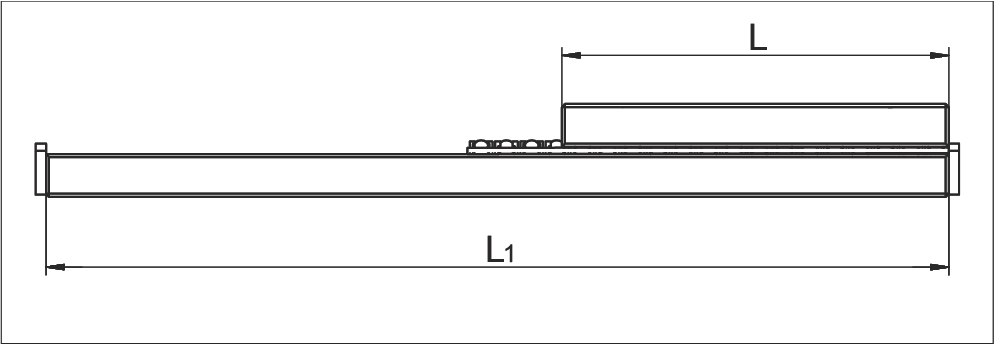

直线导轨的安装变体

Installation variants for linear guideways

直线导轨有四种安装变体。各种直线导轨也可以使用端盖形式的刮水器 (a₁)*。 在这四种情况下,会产生以下长度比率:

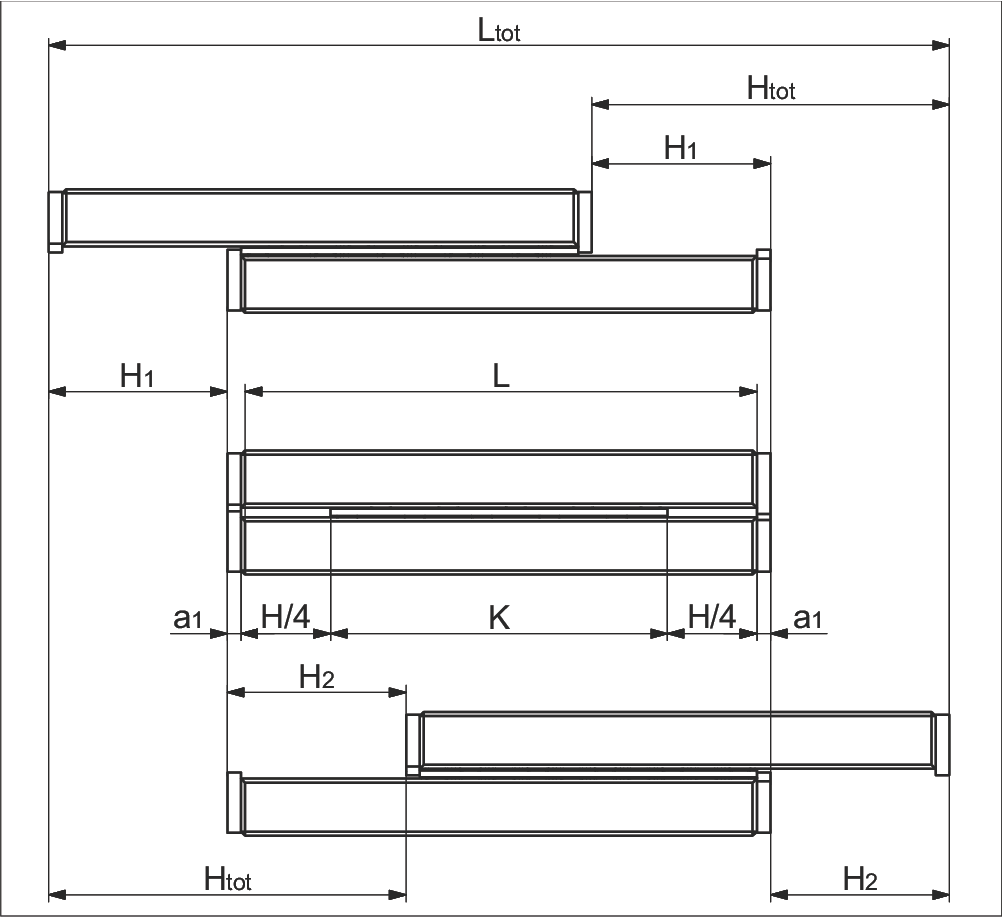

变体 1

- 等长轨道

- 对称/非对称行程

a) 无端螺钉、端盖和刮水器端盖

Without end screws, end pieces, and end pieces with wipers

b) 配备端螺钉、端盖和刮水器端盖**

For end screws, end pieces, and end pieces with wipers**

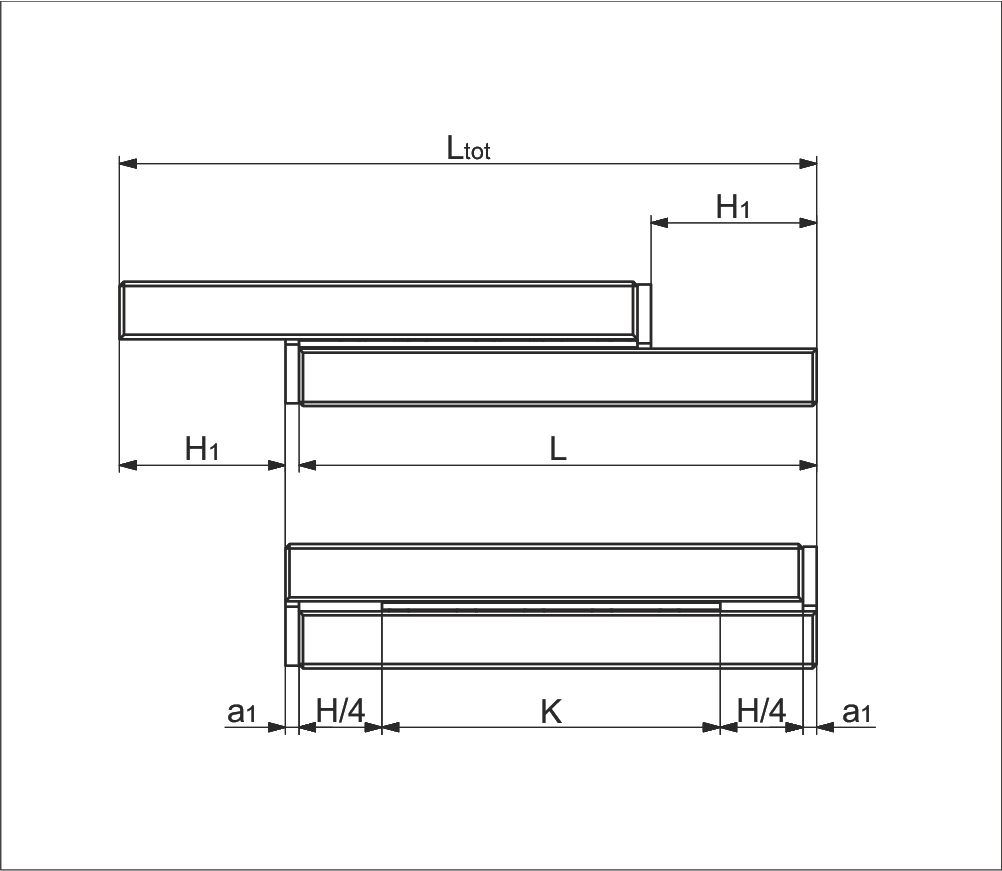

变体 2

- 等长轨道

- 单向行程

a) 无端螺钉、端盖和刮水器端盖

Without end screws, end pieces, and end pieces with wipers

b) 配备端螺钉、端盖和刮水器端盖**

For end screws, end pieces, and end pieces with wipers**

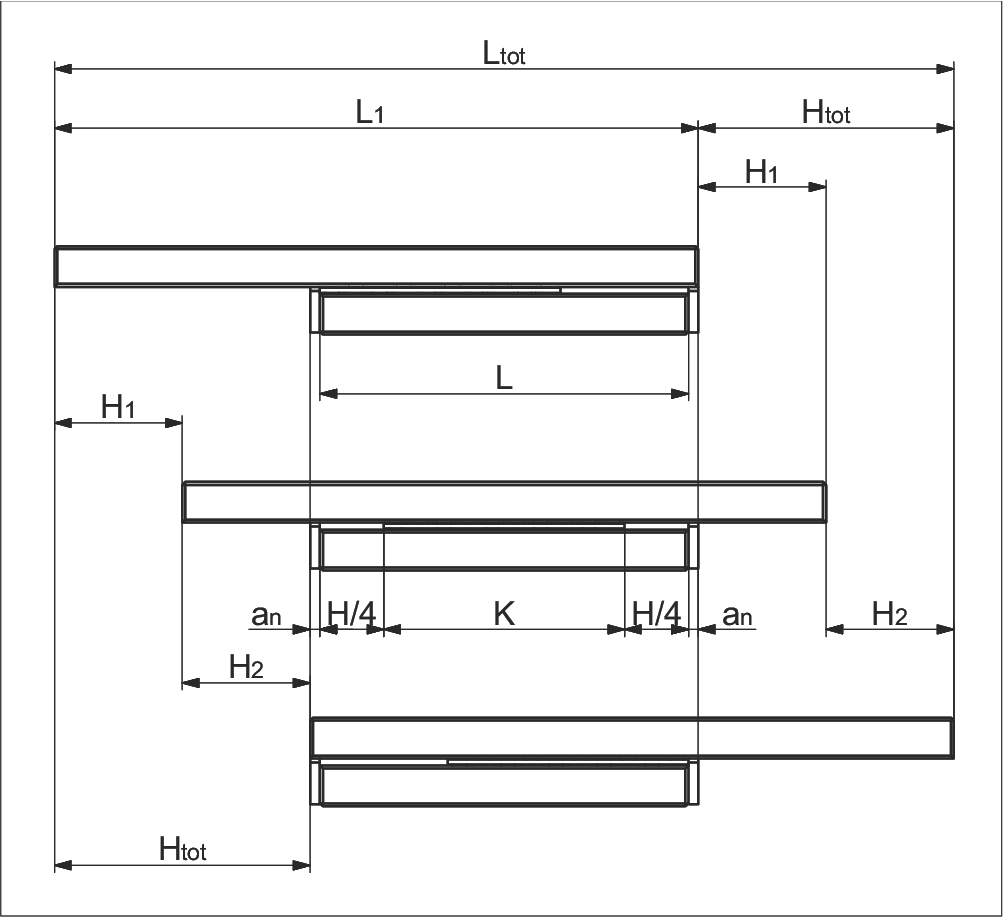

变体 3

- 不等长轨道

- 对称/非对称行程

- 短轨附加

a) 无端螺钉、端盖和刮水器端盖

Without end screws, end pieces, and end pieces with wipers

b) 配备端螺钉、端盖和刮水器端盖**

For end screws, end pieces, and end pieces with wipers**

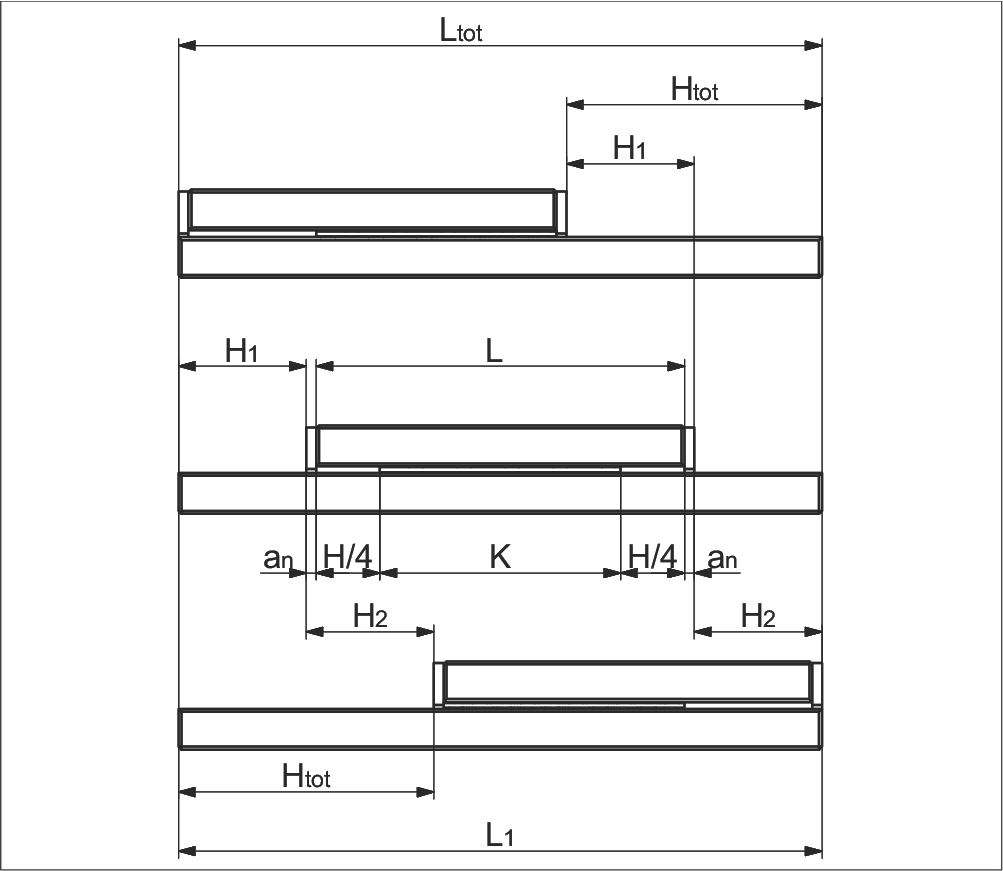

变体 4

- 不等长轨道

- 对称/非对称行程

- 长轨附加

a) 无端螺钉、端盖和刮水器端盖

Without end screws, end pieces, and end pieces with wipers

b) 配备端螺钉、端盖和刮水器端盖**

For end screws, end pieces, and end pieces with wipers**

参数说明

| K | = 滑块长度 (mm) Cage length in mm | H | = 可能行程 (mm) Possible stroke in mm |

| H₁ | = 大部分行程 = H/2 (mm) Large partial stroke in mm = H/2 | H₂ | = 小部分行程 ≤ H/2 (mm) Small partial stroke in mm ≤ H/2 |

| Htot | = 有效部分行程 (mm) Effective partial stroke in mm | H12 | = 总部分行程 = H1 + H2 (mm) Total partial stroke in mm = H1 + H2 |

| L | = 导轨长度 (mm) Length in mm | L₁ | = 长轨长度 (mm) Length in mm |

| Ltot | = 总长度 (mm) Total length in mm | an | = 端盖厚度 (mm) Thickness of the end piece in mm |

* a₁ 端螺钉、端盖和刮水器端盖,见第 5 章

** 刮水器可能会影响直线导轨的运行特性